Most people in the water treatment industry know that achieving the correct coagulant dosing level can be challenging at times. Maintaining an optimum dosage is crucial to achieving the best water quality possible, which includes an optimum reduction in organics for disinfection by-product (DBP) control. A plant operator may use historical data, jar tests, or experience to decide on their dosing level. To avoid the possibility of under dosing and releasing poorly treated water, many water treatment plants end up over dosing which results in large unnecessary chemical costs, reduced filter run times, reduced organics removal, aluminum carry over, increased sludge treatment costs etc. However, did you know that…

… no single online water quality measurement stands out as always being the best to monitor or control coagulation in all situations (as there are multiple factors that can affect coagulation)?

… some of these factors, like organics, are very critical to coagulation but are not commonly measured online and so are often overlooked?

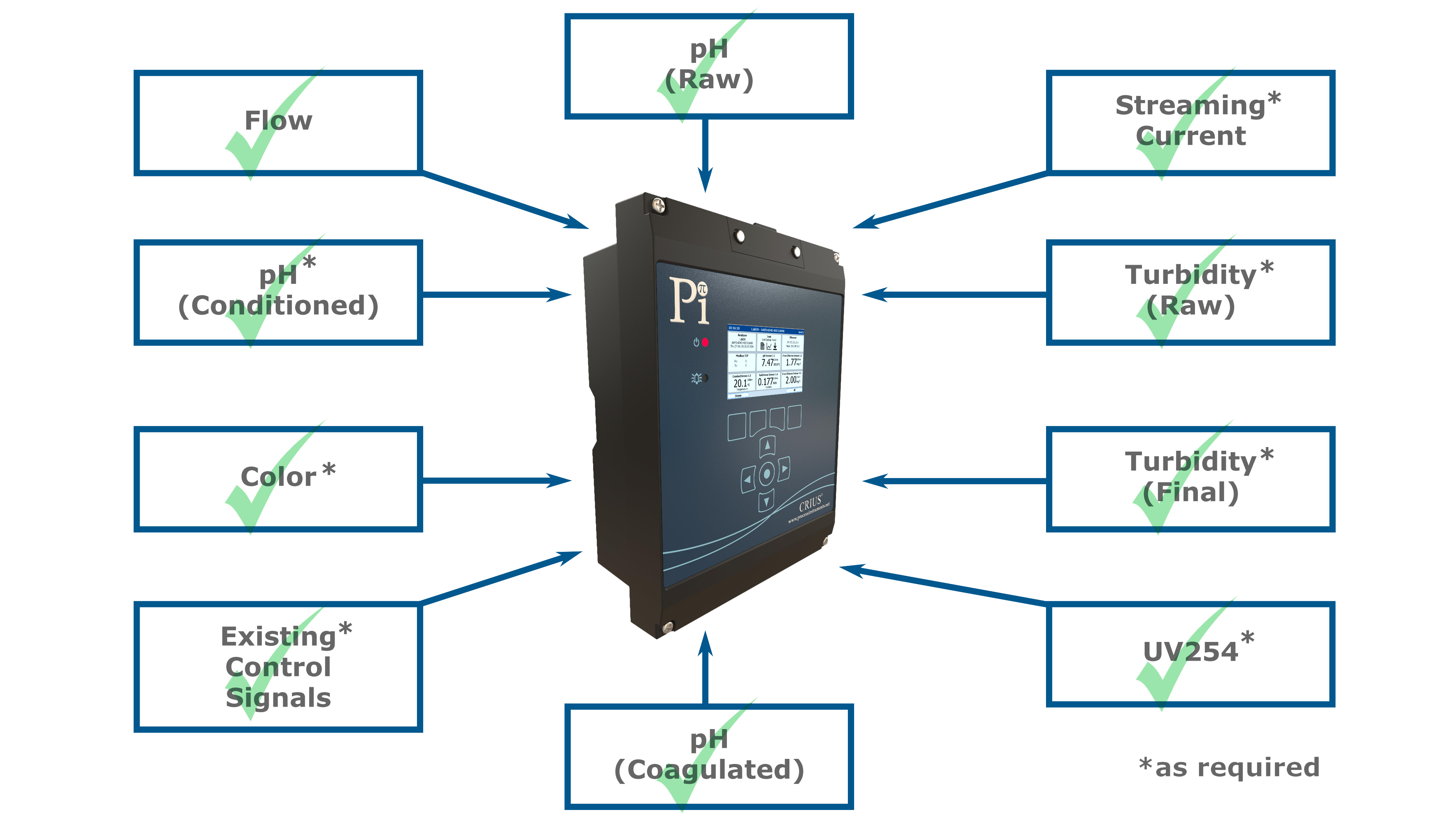

… Process Instruments controllers can monitor multiple parameters simultaneously including charge (streaming current), organics (UV254), pH, flow rate and turbidity to provide a complete overview of water characteristics minute by minute?

What is coagulation control?

Flocculation Process

Flocculation ProcessThe aim of water treatment is to remove soluble (e.g. organics) and insoluble (e.g.colloidal particulate) contaminants. These contaminants often carry an anionic charge which keeps them in suspension or in the soluble phase. Coagulants are added to neutralize the charge of colloidal particles and to also “complex” with organic molecules which ultimately results in their precipitation. Reducing the charge of the particles and precipitating the organics means they will no longer be able to remain in a stabilized suspension. Once the repulsive charge component is removed these contaminants will naturally start to clump together due to attraction forces called Van Der Waals forces. The removal of these contaminants is aided by the formation of chemical floc (resulting from the hydrolyzation of the coagulant) that both enmeshes and sweeps up the smaller agglomerations, so they can be removed more easily by sedimentation or flotation.

If the coagulant dosing is too high, the unnecessary additional coagulant can cause increased amounts of sludge to be generated, shorter filter run times, aluminum carry over, and other unwanted side effects.

This situation is made considerably more complex because the amount of coagulant required and the effectiveness of coagulation can vary greatly throughout the day or even hour by hour due to changes in turbidity, pH, temperature or the levels of natural organic material (NOM) of the incoming water.

What happens to the raw water entering a plant during a rainfall event?

The obvious answer is that incoming water gets more turbid and the coagulant dose goes up. Turbidity is used as an online measurement of water quality in virtually all WTP’s and also when jar tests are carried out, however turbidity is not the only water quality parameter that is changing. There are other factors which are critical to coagulation that are likely to be changing at the same time:

Water Treatment Site where a Coagulation Monitor might be used

Water Treatment Site where a Coagulation Monitor might be used

- Depending on the nature of the river the pH can change which in turn can increase or decrease coagulation efficiency. Each coagulant has an optimum pH range where it can achieve the highest efficiency in terms of turbidity and organics removal. Thus, changes in pH can have a considerable impact on coagulation and filtration performance, and resulting turbidity and DBP reduction.

- The alkalinity of the water can change. If this drops below around 10ppm then effective coagulation cannot occur because the hydrolysis reaction that is essential for coagulation cannot occur. This situation can only be rectified by adding alkalinity.

- The level of dissolved organics (NOM) can change. Unless monitored with appropriate instrumentation (preferably online), initial changes in organics often go unseen and under-treated as a result. The actual demand on a coagulant from organics can in some cases appear before an increase in turbidity is seen and can also remain elevated after the turbidity has returned to normal. Lack of proper instrumentation to monitor changes in organics as they occur leads to a reduced removal efficiency of NOM which can lead to the formation of Trihalomethanes and other unwanted disinfection by products.

So what is the best measurement to optimize and control coagulation?

The answer is that no one single water quality measurement provides the complete picture on its own. As has been discussed here, there are multiple factors that need to be taken into account and ideally monitored on a continuous and online basis in order to most effectively control coagulation. Expecting a single measurement parameter to be effective is simply not very practical because different water treatment plants all have different raw waters, which each have different challenges to overcome when controlling their coagulation dosing. This means that for any system to be most effective it needs to be flexible and modular, allowing different parameters to be measured based on what is needed at different water treatments plants, which depends greatly on the individual characteristics of the raw water. Even if a particular water treatment plant doesn’t currently face an issue like DBP formation due to elevated levels of organics, we have lots of examples where water quality has changed in unpredictable ways for a good many WTP’s. So, having a flexible, modular, and well rounded approach to online coagulation control, versus a single measurement approach, makes the most obvious sense.

The solution to this problem?

Not a ‘one size fits all’ product but a modular, customizable system designed to be flexible enough for all applications.

How we design your individual coagulation monitoring/control system.

StreamerSense Rugged

StreamerSense RuggedAt the heart of Pi’s coagulation monitoring/control systems is Pi’s CRIUS® CoagSense controller.

- First we will ask you for details about your particular application and water treatment challenges and from this discuss the parameters you may wish to monitor. These parameters will include one or more of the following: pH, temperature, conductivity, streaming current, UV254 and turbidity.

- We will then discuss what control and communication requirements you might need. How many dosing pumps, alarms or signal outputs are needed? Is flow pacing going to be required? Does the system run continuously or only certain hours of the day? Do you require remote access or integration with telemetry systems? If your SCADA will be handling control, then what sort of communication protocol is needed to get the measurement data integrated?

- Finally, we will discuss the ideal system installation to get the most reliable performance out of your online coagulation control system.

Once this process is complete you will have a custom designed system, created by you, specifically for your needs with all the necessary features for effective control and no unnecessary extras. You will also have a system that can be easily expanded upon should it prove necessary at a later time, or as budgets allow.

Process Instruments Coagulation Controllers – truly bespoke systems.

Coagulation Control at Midleton, Ireland

Coagulation Control at Midleton, Ireland Water Treatment Site where a Coagulation Analyzer might be used

Water Treatment Site where a Coagulation Analyzer might be used Streaming Current Analyzer installed in Cork County, Ireland.

Streaming Current Analyzer installed in Cork County, Ireland. CoagSense – Remote Access Dashboard

CoagSense – Remote Access Dashboard Flocculation Process

Flocculation Process StreamerSense Rugged

StreamerSense Rugged